Welcome to the official website of Hebei Beiteer Hydraumatic Equipment Co., Ltd.

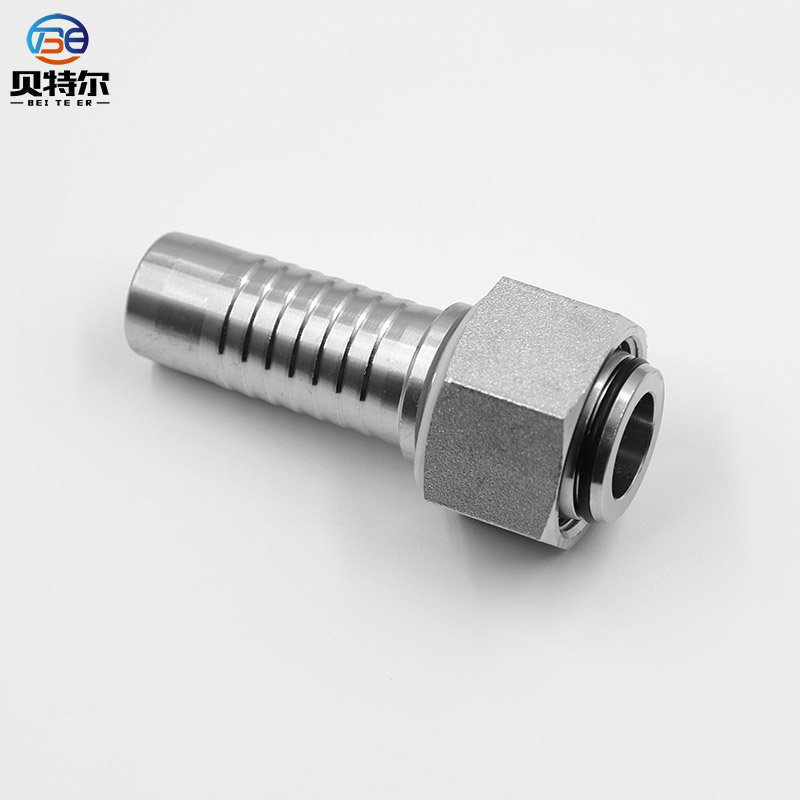

Metric 24 Degree Cone Light Series 20412

keyword:

Classification:

Products Details

The current use of transition joints is very extensive, and its main function is to play a connecting role for two different types of pipes, especially in the fields of telecommunications and electricity, its role is evident. For example, when the pipe cannot be bent due to the material, it is necessary to use an excessive joint to connect the two pipes, so that the bending effect can be achieved. In the process of installing the transition joint, it is necessary to determine whether the diameter of the pipe used is consistent with the diameter of the transition joint, and measures to prevent leakage and corrosion must be taken during the installation process. After all, whether the pipe is used as a protection for the optical fiber of the cable or as a carrier channel for transporting liquids and gases, tightness is a prerequisite that must be considered. At the same time, while ensuring sufficient sealing, anti-corrosion treatment is also required. The above is an analysis of the use of transition joints and the problems that need to be paid attention to during installation. This product is now widely used in the power and communication industries. Especially due to the rapid development of new infrastructure, the market demand for transition joints has increased significantly. Increase, understand these problems, will avoid many unnecessary troubles in the future use.

Hydraulic pipe joint is a connecting component, which is a connecting joint between high-pressure oil pipe and high-pressure oil pipe. It has many classifications, which can be divided into welded pipe joints, high-pressure hoses, transition pipe joints, high-pressure ball valves, etc. Different types of joints have different principles. Here, I will introduce the relevant principles of welded pipe joints. As the name suggests, welded pipe joints are obtained by welding, and a circular seal is used between the joint and the nozzle. The structure of the pipe joint is relatively simple, the production cost is not high, the production is relatively easy, and the sealing performance is good. However, the requirements for welding quality are very high, and it is inconvenient to install and disassemble. The cleaning of hydraulic pipe joints is divided into two types: kerosene cleaning and pickling. Kerosene cleaning is mainly for copper pipes and stainless steel pipes. First, remove the pipes and joints to be cleaned, use a cloth with kerosene to clean the interior and observe the view, and then put Both ends and joints can be directly soaked in kerosene for cleaning. The standard after cleaning is that there should be no visible contamination. Pickling is mainly aimed at heavily corroded steel pipes. First, degrease, wash with water, then remove rust, and then neutralize with lye. Be careful not to wash away the marks on the pipes.

Related Products

Six Layers of Inner Peeling Glue 87693

Metric 24 Degree Taper Weight Series 20512-RW

Inquiry Now

QUICK CONTACT

T.: +86 15030876668 (Mr. Meng)

T.: +86 15833286698 (Mr. Liang)

F.: +86 0318-4506555

E-mail: xueqing@beiteer-joint.com

WhatsApp: +86 15030876668

Facebook: +86 15030876668

Add.: No. 337 Guangchuan Street, Jingxian West Development Zone, Hebei Province, China